Advantages And Disadvantages Of Laminated Wood

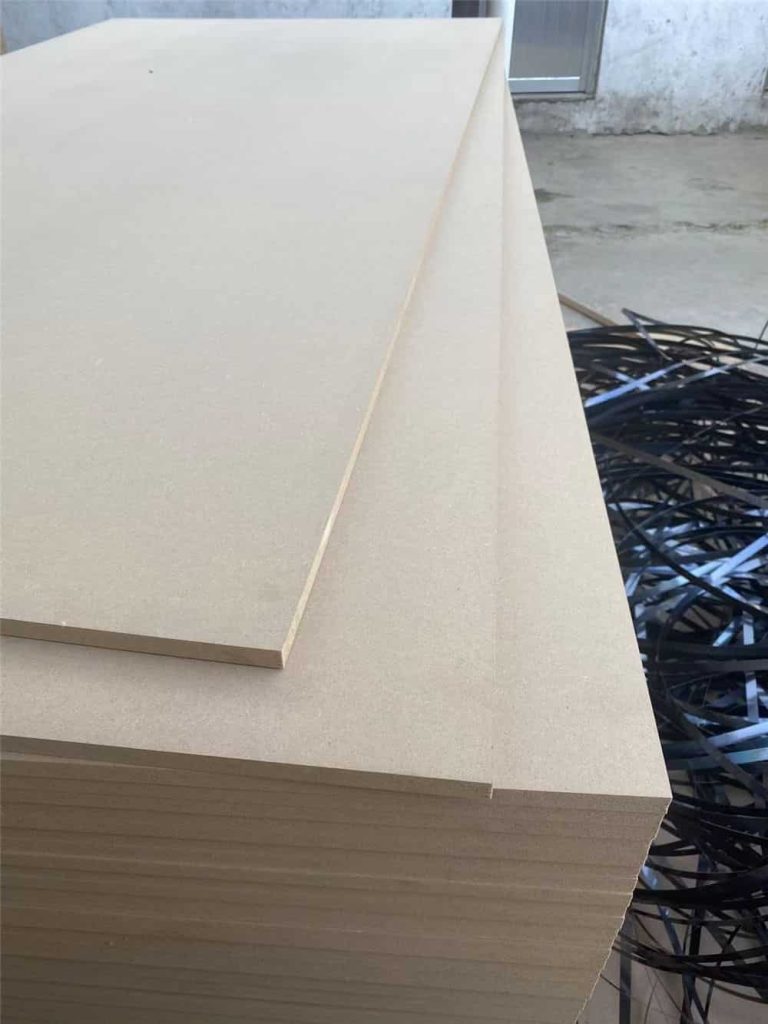

Laminated wood offers strength, durability, and design versatility but has drawbacks like moisture sensitivity and potential artificial appearance. The layered structure enhances stability, reducing warping and cracking, making it ideal for construction and furniture. It allows for various colors and patterns, mimicking expensive woods at lower costs. However, moisture exposure risks delamination. Some critics view its uniform look as lacking the character of solid wood. Additionally, high-quality laminated boards can be cost-prohibitive for budget-conscious projects. Considering these factors is crucial in deciding whether to utilize laminated wood products like Prelaminated MDF Board or Laminate Particle Board.