**Wood Veneer Laser Cutting: A Revolutionary Approach in Furniture Making**

The art of furniture making has evolved significantly over the years, with artisans and manufacturers constantly seeking innovative methods to create visually appealing and durable pieces. One such technique that has garnered attention in recent times is wood veneer laser cutting. This method involves using a laser to cut intricate patterns or designs on thin layers of high-quality wood, which are then used as decorative coverings for furniture boards. The process is not only precise but also allows for a level of detail that traditional cutting methods cannot achieve.

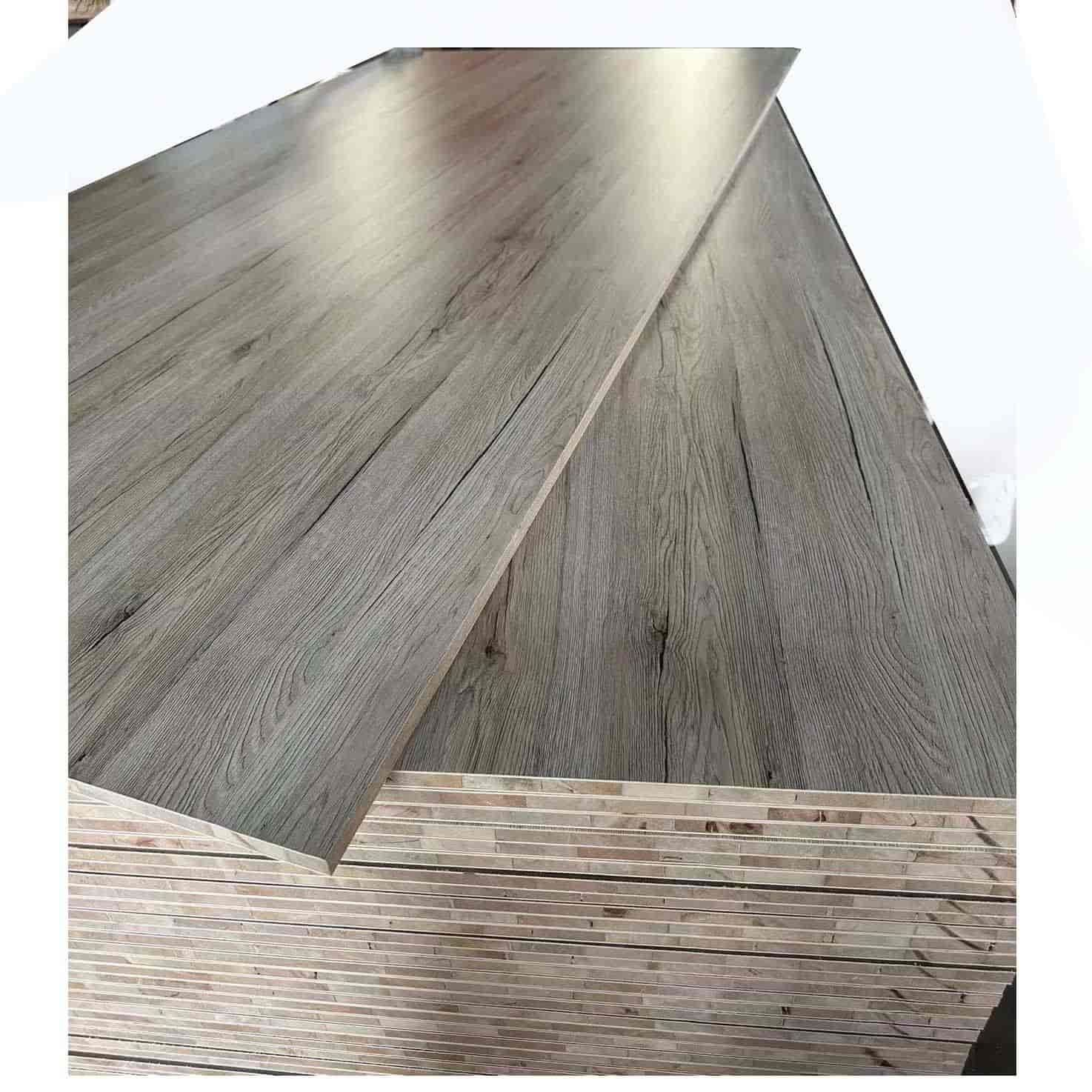

When it comes to sourcing materials for wood veneer laser cutting, large plywood sheets and buy furniture board play a crucial role. These sheets come in various sizes, with the 4X8 particle board being a popular choice among manufacturers due to its uniformity in texture and consistent quality throughout. The size of these boards makes them ideal for creating large surfaces required in many furniture pieces, including tables, cabinets, and shelving units.

For those looking to embark on wood veneer laser cutting projects, understanding the properties of different wood types is essential. Each species of wood has unique characteristics, such as grain pattern, color, and durability, all of which can affect the final appearance of the veneer. For instance, hardwoods like oak and maple are known for their strength and durability, making them suitable for heavy-use furniture pieces. Softwoods like pine, on the other hand, might be more appropriate for decorative elements or less burdensome items.

In addition to the type of wood, the quality of the large plywood sheets and buy furniture board is paramount. The boards should be free from defects such as knots, voids, or wavy grain patterns, as these can affect the accuracy of the laser cutting process and the overall look of the finished product. It is also essential to ensure that the wood veneer used is of consistent thickness to avoid any irregularities during the cutting stage.

Another critical aspect of wood veneer laser cutting is the preparation of the wood surface before the cutting process begins. Sanding the surface to a smooth finish is necessary to achieve a clean and precise cut. The application of a coating or sealant may also be required depending on the intended use of the furniture piece, as this can enhance durability and protect the veneer from moisture and damage.

Laser cutting technology itself has seen significant advancements, allowing for greater precision and complexity in the designs that can be achieved. Modern laser cutting machines can handle detailed patterns with ease, making it possible to create intricate geometric shapes, repeating patterns, or even custom designs based on customer specifications. This level of customization opens up a world of possibilities for furniture makers looking to create one-of-a-kind pieces.

In terms of the actual laser cutting process, it involves programming the machine with the desired design and then using the laser to trace and cut through the wood veneer layer. The laser’s heat vaporizes the material it comes into contact with, leaving behind a precise cutout of the programmed pattern. This method not only saves time compared to manual cutting techniques but also reduces waste by utilizing every part of the wood veneer effectively.

The applications of wood veneer laser cutting extend beyond just furniture; it also finds use in interior design elements like wall panels, ceiling decorations, and even in artistic installations. The ability to work with different wood types and finishes allows designers to tailor their projects to specific aesthetic requirements, whether it’s a rustic countryside feel or a modern, minimalist look.

In conclusion, wood veneer laser cutting represents a fascinating intersection of traditional woodworking craftsmanship and modern technology. As the demand for customized and visually striking furniture continues to rise, this method provides both artisans and manufacturers with a versatile and efficient tool to bring unique visions to life. By leveraging high-quality materials such as large plywood sheets and buy furniture board alongside sophisticated laser cutting techniques, the sky’s the limit in terms of what can be created in the realm of woodworking artistry.